Machine Embroidery Bobbin Thread (What To Use!)

This post may contain affiliate links, which means I’ll receive a commission if you purchase through my links, at no extra cost to you. I sometimes receive free products for review. Please read disclosure for more information.

Using the wrong embroidery bobbin thread in your machine can cause thread breaks, skipped stitches, and even tension problems. And, one frustrating aspect for beginners is that machine manuals (well, mine, at least) lack in-depth details regarding compatible threads.

Here’s what machine embroidery bobbin thread is and how to choose the right one for your machine!

Choosing an Embroidery Bobbin Thread

Embroidery stitches are created from two threads: a top thread from the spool and a bottom thread from the bobbin.

Now, embroidery bobbin thread is NOT the same as regular embroidery thread or sewing thread, and these types are NOT interchangeable.

Since bobbin thread is specially formulated to go on the underside of an embroidery design and work smoothly with your machine, your best embroidery results happen when you purchase a thread that says it is specifically made for the bobbin. Don’t just wind regular embroidery thread on a bobbin and stick it under your throat plate!

Your user manual is the best place to learn what to use for your embroidery machine.

However, threads differ in weight, quality, color, and fiber composition. Whew! Here’s a quick discussion of the different types of bobbin threads you could use with your embroidery machine. (And as a word of advice, always remember to first test new threads on a sample project rather than an expensive embroidery blank!)

1. Bobbin Thread Fiber Composition

The most popular embroidery thread fiber types for the top thread spool are rayon, polyester, and cotton. The same is true for bobbins, and as with regular embroidery thread, the way bobbin threads are constructed can vary also.

For my machines, I prefer polyester bobbin thread. However, I also use cotton embroidery bobbin thread (harder to find than polyester!) for items that need to go in the oven or microwave since heat isn’t a friend of polyester or rayon.

2. Thread Colors

Imagine having a design with 30 color changes. Do you have to change the bobbin thread 30 times to match?

Thankfully, the answer is no! That’s because embroidery designs are digitized so bobbin thread will not show on an embroidery blank’s top.

Unless the back of the design is visible, there’s no need to pay attention to bobbin thread colors.

In fact, embroidery bobbin thread only comes in a few colors (black and white most often, although Madeira does have multicolored Bobbinfil). So, you’re limited in what you can wind using actual bobbin thread anyway.

Thus, the only times I match my bobbin color to the top thread color are when creating free-standing lace or other projects where the back of the blank is visible. (Examples include embroidering in-the-hoop projects like coasters with satin or decorative stitch borders or even faux-leather teardrop earrings.) In these cases, I wind bobbins with regular machine embroidery thread.

3. Choosing Bobbin Thread Weight

Thread weight refers to the thickness of a sewing or embroidery thread. A larger weight number correlates to a thinner thread.

Unlike sewing, where you typically match the bobbin thread to the top thread, the bobbin thread for an embroidery machine is finer than the top thread. One reason for this thinner bottom thread is to keep dense designs from having too much thread bulk on the underside of the design, which can affect how the design looks and lays.

Most embroidery designs are digitized for standard 40-weight embroidery thread. Thus, the recommended bobbin thread weights are almost always 60 weight or higher.

For all Brother embroidery machines I’ve owned (Brother SE625, SE1900, and Luminaire XP2), the recommended bobbin thread is 60-weight thread. Some other embroidery machines use 90-weight thread, so check your user manual for the preferred weight.

4. Brands

Some machine brands recommend a specific thread brand, but I’ve found my Brother embroidery machines accept multiple brands.

Now, most major thread manufacturers make a version of embroidery bobbin thread (sometimes also called Bobbin Fill or Bobbin Fil thread.)

For instance, dime, Sulky, Madeira, Mettler, Aurifil, OESD, Robison Anton, and even Brother have their own bobbin threads to wind yourself. The fibers, thread construction methods, and weights vary.

Of course, you can also purchase pre-wound bobbins on the cheap from Amazon, although quality can vary.

5. Checking Thread Quality

Above is an example of a fuzzy pre-wound bobbin. This is a BEAST to clean up after, and I do not recommend using it! Unless you love cleaning lint from your embroidery machine bobbin compartment, choose a good-quality thread with minimal fibers fuzzing out.

The ideal thread will look thin and be smooth and strong when you run your fingers over it.

Pre-Wound Embroidery Bobbins vs. Winding Bobbins Yourself

In my opinion, pre-wound bobbins are well worth the expense and the occasional troubleshooting. Especially since they are wound full and last longer than bobbins I wind myself. (My machine stops winding about 3/4 of the way full.)

I purchased a new box of 144 pre-wound bobbins about six months ago, and it’s barely half empty after roughly 4 million stitches created since opening. (Each bobbin lasts around 50,000 stitches, I’d say, although this is wildly dependent on stitch length and type, of course.)

When purchasing pre-wound bobbins, check if they will be compatible with your embroidery machine and if you need to use a different bobbin case than the standard. Specifically, verify:

- Thread weight and composition

- Bobbin size and material

Most pre-wound bobbins come with plastic sides, but you can also find paper sides or no core.

Issues with Pre-Wound Bobbins I’ve Had

As mentioned, the occasional pre-wound bobbin problems are well worth the time saved by not winding my own. However, pre-wound bobbins aren’t always without issues.

- If your machine suddenly stops recognizing that the bobbin thread is running low or is empty, it might be a poor-quality bobbin or the wrong type of pre-wound.

- I’ve also had pre-wound bobbins not work with my automatic jump stitch cutter.

- Bobbins wound too full sometimes need to be unwound a bit before they fit in the bobbin case.

- Pre-wound bobbins can jump around more and make a rattling sound, especially when nearing the end of the bobbin.

Tips for Winding Embroidery Machine Bobbins

If you wind your bobbins, have a small army of wound bobbins on hand before starting each project. It’s no fun to stop a design and wind a bobbin!

Be careful to wind the bobbin with even tension. If it is threaded too tightly or too loosely, you may have problems. Also, the thread must be evenly distributed along the bobbin center and not all wonky on one side.

Using a slower speed helps with even winding and allows you to catch issues before they start. (Has anyone else ever wound the thread underneath the bobbin instead of on the bobbin?!)

Lastly, make sure the thread tail of the wound bobbin is trimmed close to the bobbin to keep it from interfering later with thread feeding.

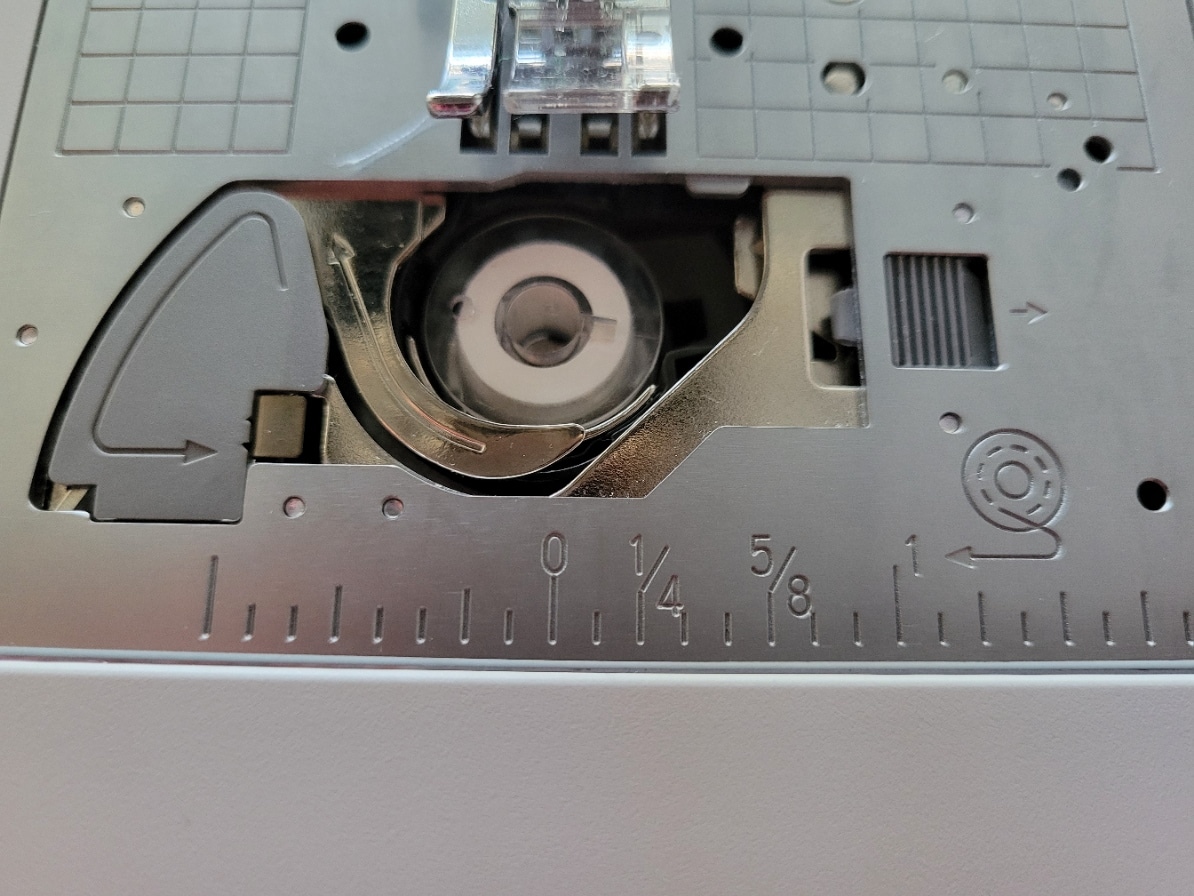

Inserting the Bobbin the Right Way

Yes, you can put an embroidery bobbin in the wrong direction and cause stitching issues! Thus, verify the orientation before placing the bobbin.

For all my Brother embroidery machines, the diagram on the machine’s base reminds me of the correct direction: with the thread coming off on my left.

Bobbin Sizes

While you shouldn’t use the same bobbin thread for embroidery as sewing, you can use the same bobbins themselves for sewing and embroidery if you own a combination machine.

The most popular bobbins for home embroidery machines are 7/16″ plastic bobbins. Depending on the brand, they may be known as Size A, Class 15, or SA156 bobbins.

However, not all embroidery machines use the same type of bobbin (some use Style M, Style L, etc.), so it’s essential to check the user manual for your machine to determine the right size.

And, don’t substitute metal bobbins or plastic bobbins that “look the right size” with the ones meant to go on your machine.

Adjusting Bobbin Tension When Required

If you’re troubleshooting embroidery issues, adjusting the bobbin tension isn’t the first troubleshooting step you should try. In fact, I never adjust the bobbin tension on my primary bobbin case. (It’s super hard to get back to where it was.)

However, if you’re doing bobbin work or are at your wit’s end with troubleshooting, you may need to adjust the bobbin tension.

For most Brother home embroidery machines, this is done by adjusting the tension screw (the slotted-head one) on the bobbin case using a small screwdriver.

Turning clockwise increases the tension. (Righty-tighty, lefty-loosey.) Always make small changes when adjusting.

Different Cases for Different Tasks

Check which bobbin case to use with pre-wound bobbins as this might be different than the one you use with bobbins you wind yourself.

Many embroidery machines will come with two bobbin cases. In the case of my Brother embroidery machines:

- The bobbin case with the green screw is the standard bobbin case.

- The second is for pre-wound bobbins or adjusting as needed.

Changing Bobbins During Projects

Ideally, I’d start each embroidery project with a full bobbin. However, sometimes the stitch count is more than one bobbin can handle, or I want to use up some half-wound bobbins.

Before changing the bobbin on your embroidery machine, make a few reinforcement stitches to keep threads from loosening, trim your thread, remove your hoop, and replace the bobbin. Set the machine up again and start stitching.

If the bobbin thread runs out and your machine doesn’t alert you as it keeps stitching, all you need to do to fix the issue is back up to the position where the bobbin thread ran out and start stitching there.

Handy Storage Ideas

When you try to store bobbin thread ends, they run all over the place! Here are a few suggestions for keeping mine tidy.

First, I love my little bobbin thread clips shown above. They let my bobbins rest in the case I got from Hobby Lobby.

Another fun option is the bobbin ring that holds bobbins firmly within its sides.

To wrap things up, the best embroidery bobbin thread is the one that your machine manufacturer recommends, so always check your user manual. However, knowing the general rules can help you troubleshoot issues and create more than just standard embroidery projects!

Where do your purchase your pre-wound bobbins from?

Usually Amazon, Designs in Machine Embroidery, or my local dealer if I’m in a pinch.

Brother Support told me to use Guterman embroidery bobbin thread. Is there a specific bobbin thread that is made only for embroidery or is any correct weight bobbin thread okay to use for embroidery? Is embroidery bobbin thread weaker or somehow different than other bobbin threads?

Your Brother embroidery manual will tell you exactly what weight of thread your machine needs in the bobbin. The machines I own require 60wt bobbin thread, but that’s not the case for all Brother machines. Also, embroidery bobbin thread is not the same as the top embroidery thread or regular sewing thread–you do need to buy specifically embroidery bobbin thread. Brother actually makes their own version of bobbin thread (there are lots of other brands that should work on machines also), but you could also use Gutermann thread.